PP coroplast hollow corrugated sheet making machine

Pp corrugated sheet is also called as PP hollow sheet, PP flute sheet, Coroplast sheet....

PP corrugated sheet application :

PP coroplast hollow corrugated sheet making machine

Pp corrugated sheet is also called as PP hollow sheet, PP flute sheet, Coroplast sheet....

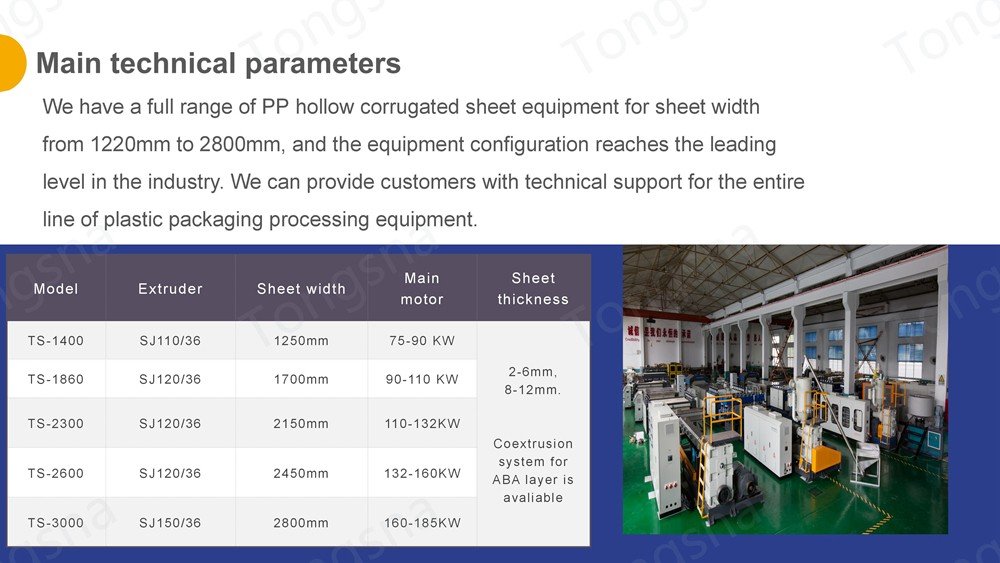

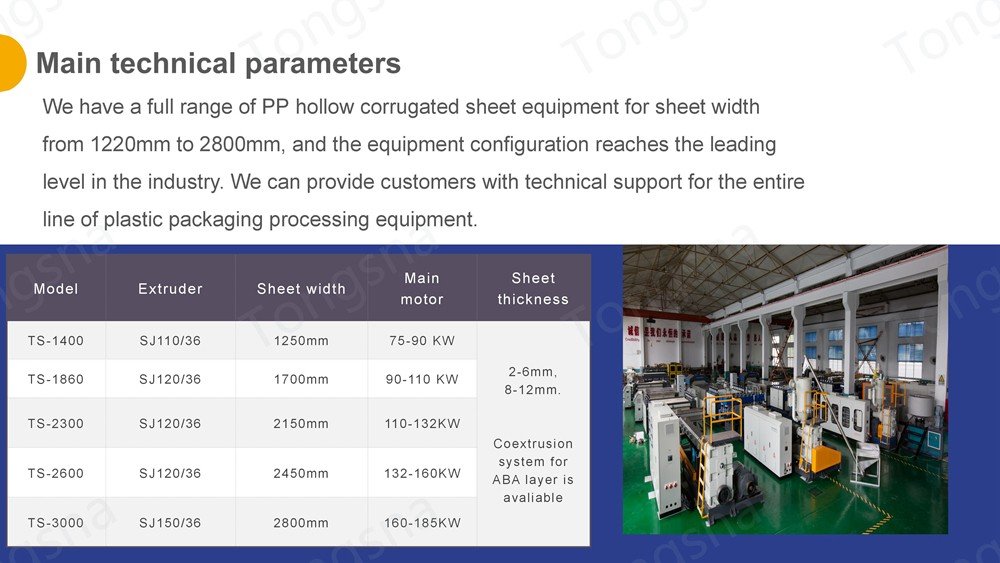

Tongsan has different models of PP flute sheet extrusion machine,

the sheet width can be 1200-3000mm,

the sheet thickness can be 2-12mm.

PP coroplast hollow corrugated sheet making machine

Pp corrugated sheet is also called as PP hollow sheet, PP flute sheet, Coroplast sheet....

PP corrugated sheet application :