OUR PRODUCTS

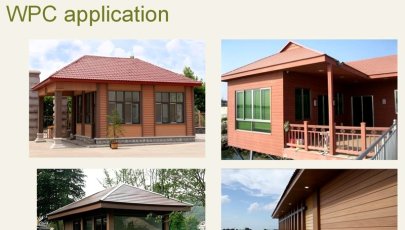

Tongsan Wood Plastic WPC machine is developed for using recycled PP/PE plastic mixing with agriculture wastage(such as wood sawdust, rice husk, rice straw, wheat straw) to make eco-friendly construction products, the max. wood percentage can be 70%. The Wood Plastic WPC machine is used for making WPC profiles by Wood and Plastic composition, such as WPC decking, WPC wall cladding, WPC fencing, WPC pergola, WPC post, etc...

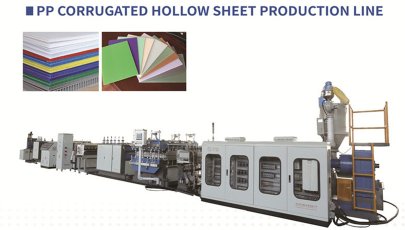

Tongsan PP flute sheet extrusion machine is used for making Pp corrugated sheet, the sheet width can be 1200-3000mm, the sheet thickness can be 2-12mm. Tongsan is professional manufacturer with rich experience for turnkey production line.

We have the complete WPC PVC DOOR MAKING machines in our factory stock now. we have rich experience for providing turnkey project for WPC door making machine to dfifferent countries. if you are interested, we can also take you to visit our customer's factory to check the processing for making complete WPC doors from raw material to final product.

Tongsan high speed plastic corrugated pipe machine can reach production speed for 20-30m/minute, it equip with 72 pairs of mold blocks with high speed corrugated pipe forming machine

this machine is used for making 40-110mm double wall corrugated HDPE pipe. The extruder adopts high-efficiency screw, the die head adopts double-layer spiral structure, mold die and core die being nitrided, the forming machine adopts vacuum forming type, equipped with automatic lubrication system.

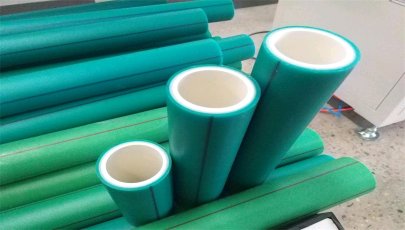

PPR/PP/PE pipe extrusion line is capable of manufacturing different sorts of pipes such as PPR cold/hot water pipes, PE pipes, silicone pipes.

Tongsan high speed plastic corrugated pipe machine can reach production speed for 20-30m/minute, it equip with 72 pairs of mold blocks with high speed corrugated pipe forming machine

this machine is used for making 40-110mm double wall corrugated HDPE pipe. The extruder adopts high-efficiency screw, the die head adopts double-layer spiral structure, mold die and core die being nitrided, the forming machine adopts vacuum forming type, equipped with automatic lubrication system.

SBWG-315 double - wall corrugated pipe production line can continuously produce HDPE double - wall corrugated pipe and this line can achieve on-line belling. The machine has the function of automatic demoulding when power is off. The extruder adopt high-efficiency screw, the die head adopts double-layer spiral structure, mould die and core die being nitrided , The forming machine adopts vacuum forming type, equipped with automatic lubrication system.Forming mould is made of aluminium alloy, adopt water cooling type. The pipe can be cut by on-line cutting machine automatically.

Double layer single wall corrugated pipe making machine This machine is equipped with two extruders for making double layer(double color ) single wall corrugated pipe. This is high speed corrugated pipe machine with water cooling for the forming machine, the production speed can be 20-30 meters per minute.

This double wall corrugated pipe making machine equipped with double layer spiral structure extrusion die head. Forming machine adopts vacuum forming type. This production line can produce PP,PE etc material small diameter double wall corrugated pipe continuously and stably. Plastic double wall corrugated pipe has the features of corrosion resistance, wear resistance, high strength, flexibility etc.

plastic single wall corrugated pipe extrusion line can produce PP/PE/EVA/PVC/PA corrugated pipe. Corrugated pipe produced by our machine has the features of high production speed, even corrugated shape,straight pipe seam,and smooth surface.

This production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.

Tongsan PP hollow corrugated sheet extrusion machine can produce the sheet with the width of 1220-2800mm. With continuous improvement in the field of hardware and software, new and optimized electronic control system, original designed fast cooling and calibrating design, high-precision haul off and cutting control, Tongsan PP corrugated hollow sheet machine has the advantages of stably production, high efficiency, superior quality of finished product, wide adaptability of raw material.

This production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.

This production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.

Qingdao Tongsan Plastic Machinery co.,Ltd have been develop the PP hollow corrugated sheet making machine since 2015,now we have the machines for the PP hollow grid plate width from 1220mm to 2450mm and thickness from 1.5mm to 12mm.We have different model production line,such as the 1400 type PP hollow sheet extruder machine,1860 type PP corrugated sheet production line,2300 type PP hollow corrugated board making machine,2600 type plastic hollow grid panel making machine,and for each model,we have the co-extrusion type for customer choose.The co-extruder type can use 20%-60% fillermatch for reduce the cost,so our customer can produce the cost competitiveness sheet with goog quality.Our machine have the advantage of high output,easy operation,high precision,good products with smooth surface straight rib.

This production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.

Tongsan Wood Plastic WPC machine is developed for using recycled PP/PE plastic mixing with agriculture wastage(such as wood sawdust, rice husk, rice straw, wheat straw) to make eco-friendly construction products, the max. wood percentage can be 70%. The Wood Plastic WPC machine is used for making WPC profiles by Wood and Plastic composition, such as WPC decking, WPC wall cladding, WPC fencing, WPC pergola, WPC post, etc...

We have the complete WPC PVC DOOR MAKING machines in our factory stock now. we have rich experience for providing turnkey project for WPC door making machine to dfifferent countries. if you are interested, we can also take you to visit our customer's factory to check the processing for making complete WPC doors from raw material to final product.

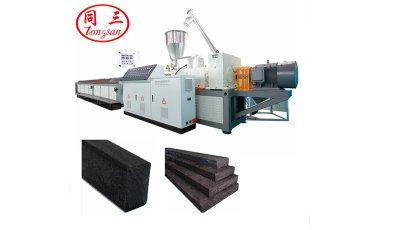

WPC board making machine SJMS80/156 Foam board production line

WPC decking profile making machine complete WPC production process We supply turnkey production line for WPC production with turnkey production plant.

This machine is used for making Plastic lumber by using recycled PE plastic scrap. the finished product can be widely used for making plastic furniture.

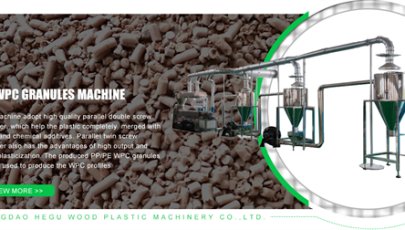

This production line is suitable for producing PP/PE WPC granule. The machine adopt high quality parallel double extruder, it can help the plastic completely be merged with wood and chemical additives and it has the advantages of high output and good plasticization. The PP/PE WPC granules are used to produce the WPC profiles, which ensures the products more durable.

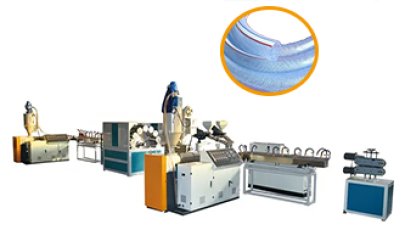

PPR/PP/PE pipe extrusion line is capable of manufacturing different sorts of pipes such as PPR cold/hot water pipes, PE pipes, silicone pipes.

The machine can be used to make pvc spiral reinforced pipe. the total production line inclouding two extruders,forming device,water tank and winder. The pipe wall presure is reinforced by spiraling soft pvc and hard pvc. This kind of pipe has features of compression resistance,resisting strong corrosion and possitive or negative pressure,bent-resistant, good liquidity,etc,it is suitable for carrying the gas,liquid,power and granules. The pipe is widely used in industy,agriculture,construction and water conservancy irrigation,etc.

This production line presents concial double screw extruder as the hose machine, and equips different pipe die heads and relevant auxiliary machines.

Our Main Products are: 1, Wood Plastic WPC Decking Profile machine 2, WPC Door Making Machine 3, WPC Board Making Machine 4, Plastic Corrugated pipe machine 5, PP hollow sheet making machine 6, plastic sheet extrusion machine 7, PE PVC PPR pipe extrusion machine

Our Main Products are: 1, Wood Plastic WPC Decking Profile machine 2, WPC Door Making Machine 3, WPC Board Making Machine 4, Plastic Corrugated pipe machine 5, PP hollow sheet making machine 6, plastic sheet extrusion machine 7, PE PVC PPR pipe extrusion machine

This is high speed PVC pipe production line which can produce 4 pieces of PVC pipes at the same time, the suitable production diameter is 16-40mm.

Tongsan PP hollow corrugated sheet extrusion machine can produce the sheet with the width of 1220-2800mm. We can provide all the auxiliary machine for plastic pp hollow sheet to make box, such as edge sealing machine, die cutting machine, printing manchine, welding machinery etc. The PP hollow sheet/corrugated sheet is widely used in fields of machinery, electron, appliance, food, advertising. interior decoration material, glass, agricultural product etc packing and transporting.

Tongsan PP hollow corrugated sheet extrusion machine can produce the sheet with the width of 1220-2800mm. With continuous improvement in the field of hardware and software, new and optimized electronic control system, original designed fast cooling and calibrating design, high-precision haul off and cutting control, Tongsan PP corrugated hollow sheet machine has the advantages of stably production, high efficiency, superior quality of finished product, wide adaptability of raw material.

The PVC WPC wall panel extrusion line is suitable for producing the wall panel. The wall panel can be coated with colorful decorative films.

This production line can produce PE, PP, ABS, PMMA, PC, PS, HIPS single layer or multi-layer plastic sheet product. The maximun width of the product is 2000mm, the thickness range from 1mm to 20mm. Plastic sheet is widely used in refrigerators, air conditioners, advertising, construction, environmental protection, chemicals, sanitary ware, car interiors and other fields.

The wood-plastic is a new kind of synthetic material which uses PVC,PP,PE resin or recycled plastic and plant fibre ( wood powder,chaff,straw etc.) as raw material and through the process of mixing,granulation,exrusion,calibrating,drawing off and cutting. This kind of wood-plastic materials are not only very similar with natural wood in appearance and feel,but also with the same characteristics as wood of excisable, planeable,sawable, unmatched grip,low bibulous rate, good moisture resistance, mothproof,mildew resistance,good resistance to acid and alkali,anti-corrosion, and it has the feature of fire resistance.The products are non-toxic,non-polluting,environment-friendly and save-energied, without formaldehyde, benzene and ammonia and other harmful substances.The wood-plastic products are widely used in outdoor floor,hydrophilic construction,balcony,landscape architecture,chairs and benches, fences, indoor doors and windows, furnitures, etc.

Application of wood plastic WPC products The wood-plastic is a new kind of synthetic material which uses PVC,PP,PE resin or recycled plastic and plant fibre ( wood powder,chaff,straw etc.) as raw material and through the process of mixing,exrusion,calibrating,drawing off and cutting. This kind of wood-plastic materials are not only very similar with natural wood in appearance and feel,but also with the same characteristics as wood of excisable, planeable,sawable, unmatched grip,low bibulous rate, good moisture resistance, mothproof,mildew resistance,good resistance to acid and alkali,anti-corrosion, and it has the feature of fire resistance.The products are non-toxic,non-polluting,environment-friendly and save-energied, without formaldehyde, benzene and ammonia and other harmful substances.The wood-plastic products are widely used in outdoor floor,hydrophilic construction,balcony,landscape architecture,chairs and benches, fences, indoor doors and windows, furnitures, etc.

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc.

This machine is used for laminating the door panel which with pattern on the surface.

The machine is used for processing the keyholes on the front and side of the door panel.

The machine is used for coating the film on the door frame surface.It adopts the two-component adhesives and the consumable cost is low.

The machine is used for cutting color film into different sizes. The film can beused for laminating the door panel, door frames, profiles, etc.

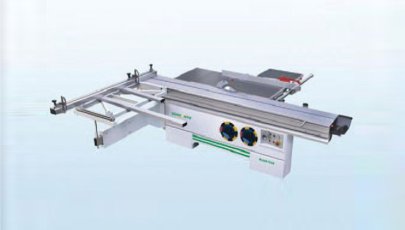

This machine is used for cutting door panels with fixed length and profile line at a certain angle.

INTRODUCTION

Qingdao Tongsan Plastic Machinery Co, Ltd. hasdeveloped from a single

corrugated pipe equipment production

plant to a diversified professional extruder manufacturer with corrugated

pipe equipment, hollow board equipment, and wood plastic production lines after 26 years.

Our development is inseparable from the support of our customers and friends. For 26 years,

we have provided hundreds of production lines to customers in more than 50 countries.

Our equipment is our constant pursuit to create the greatest value forcustomers.

26 years manufacturer for Plastic extruder machines

Customer in more than 50 countries

80professional enginner

5Q Strict quality control with CE

EVALUATION

NEWS&EVENTS

Get in touch with us

Telphone: 0086-532-82215318 0086-532-82221583

E-mail: manager@tongsanextruder.com

Address: The west end and south side of Yangzhou rood, Jiaozhou city,Qingdoo, China.

Get Free Quote