PP PE Wood Plastic Composite WPC decking production machine turnkey plant

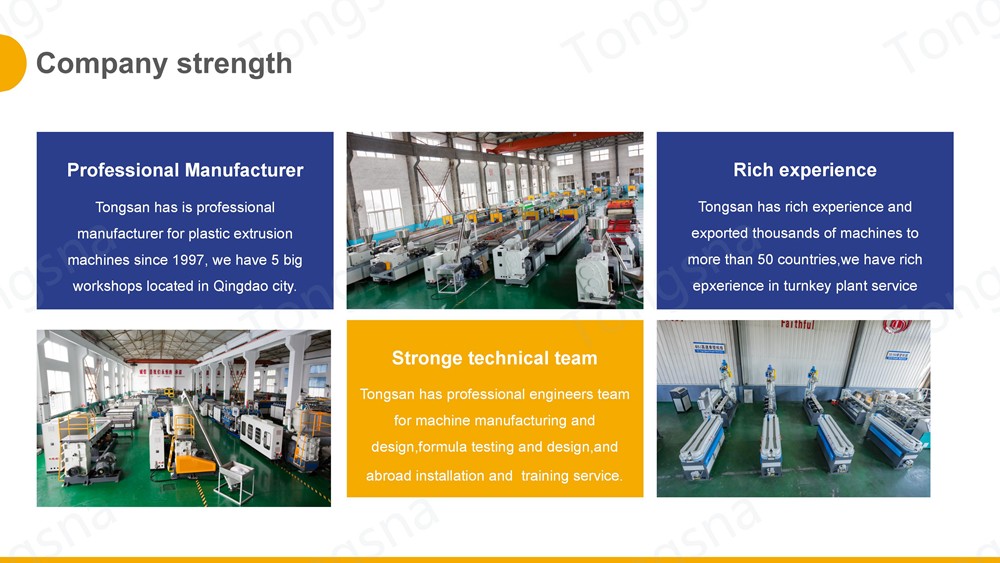

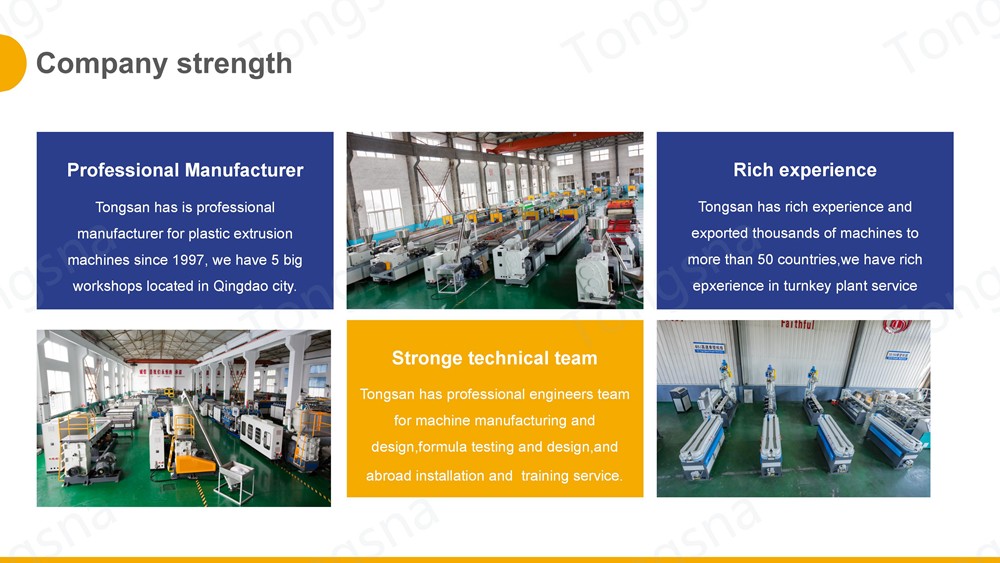

Tongsan is professional for the WPC turnkey production plant, with experienced low cost formulation, reasonable and advanced machine design, strong technical team, oversea engineer service.

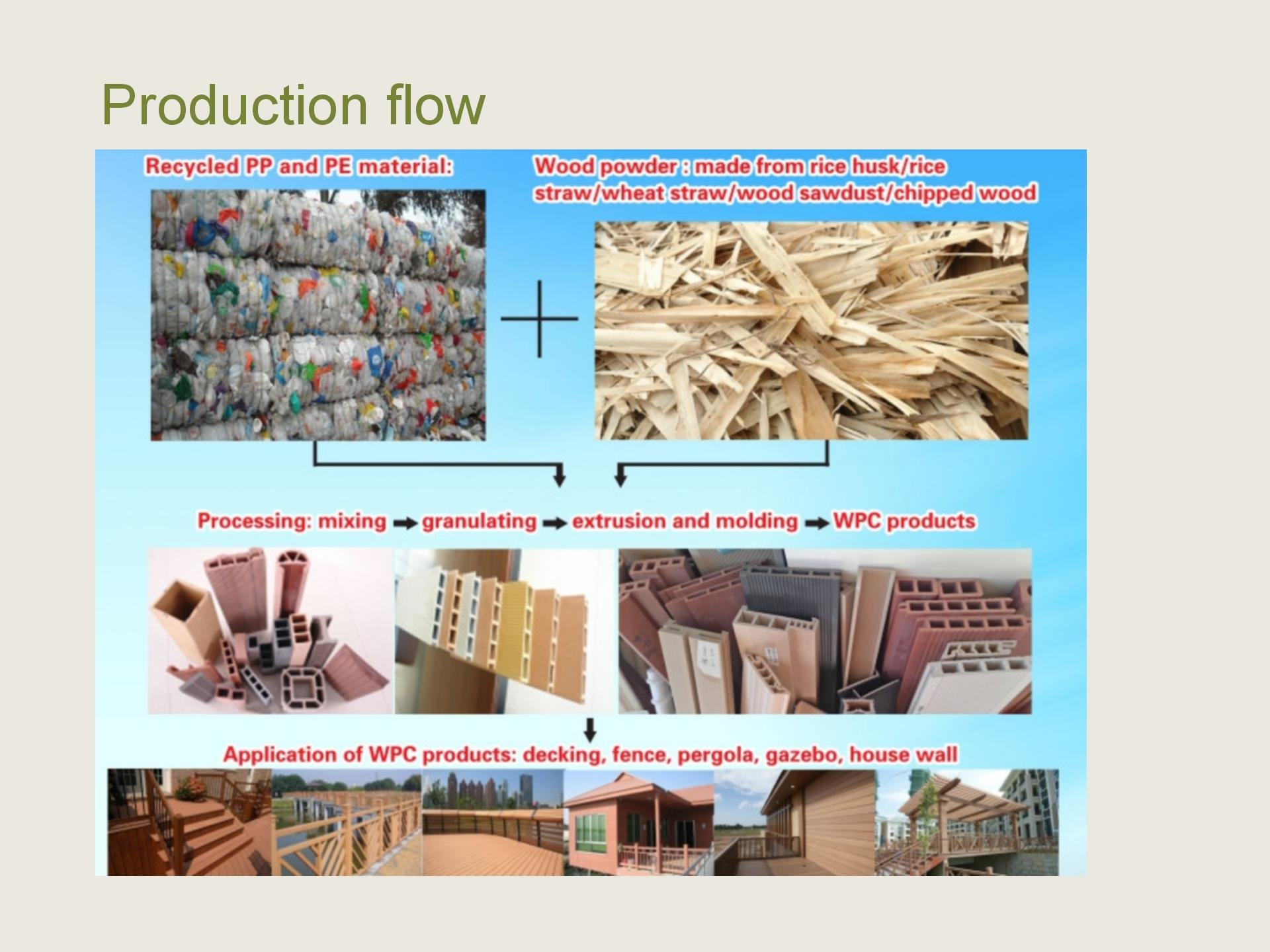

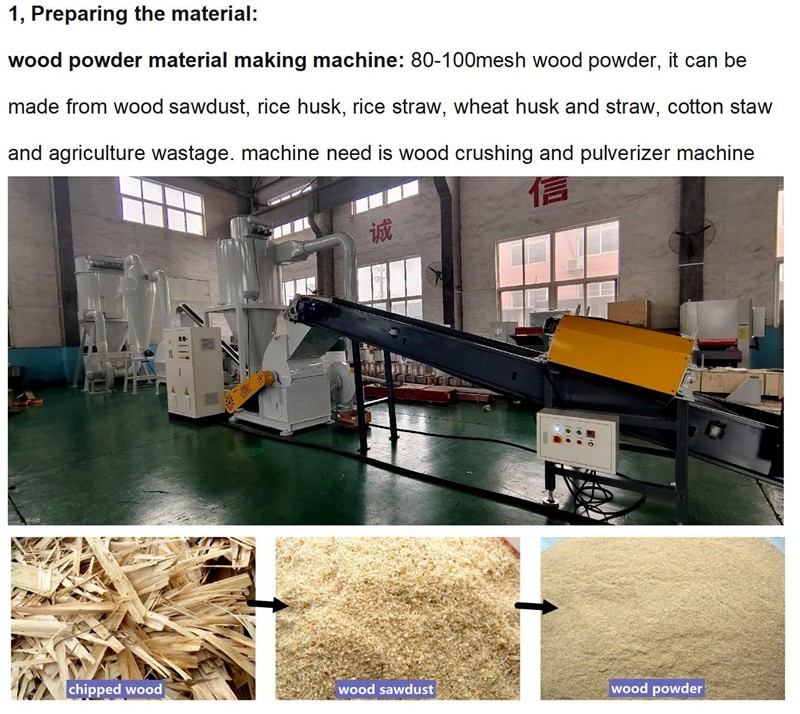

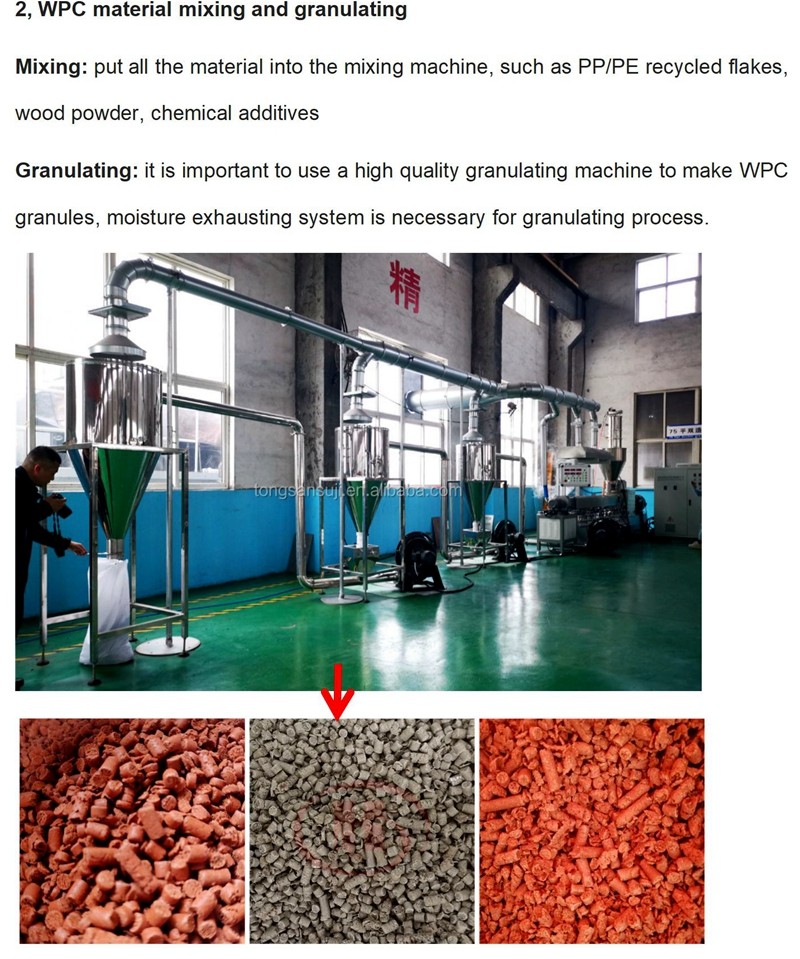

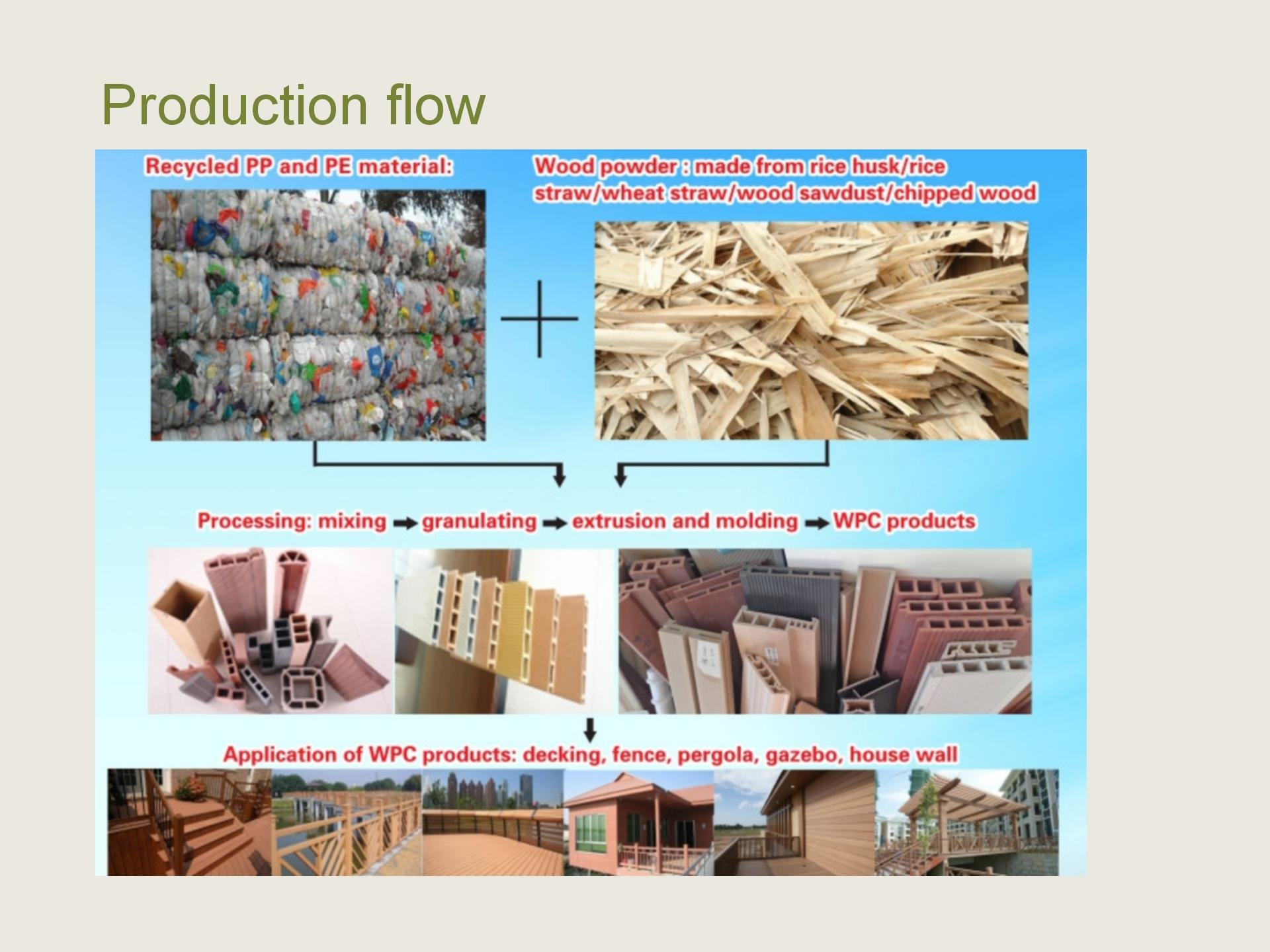

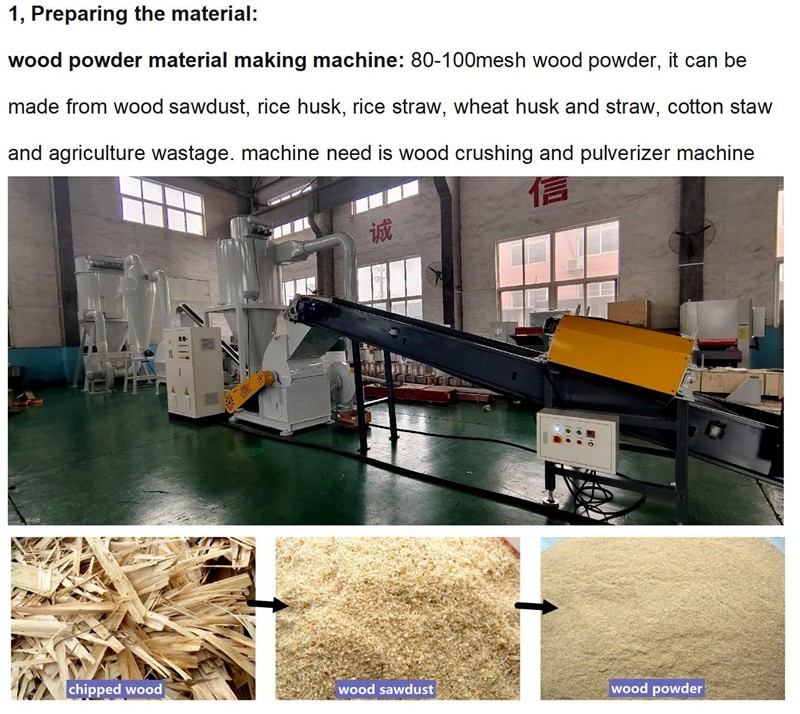

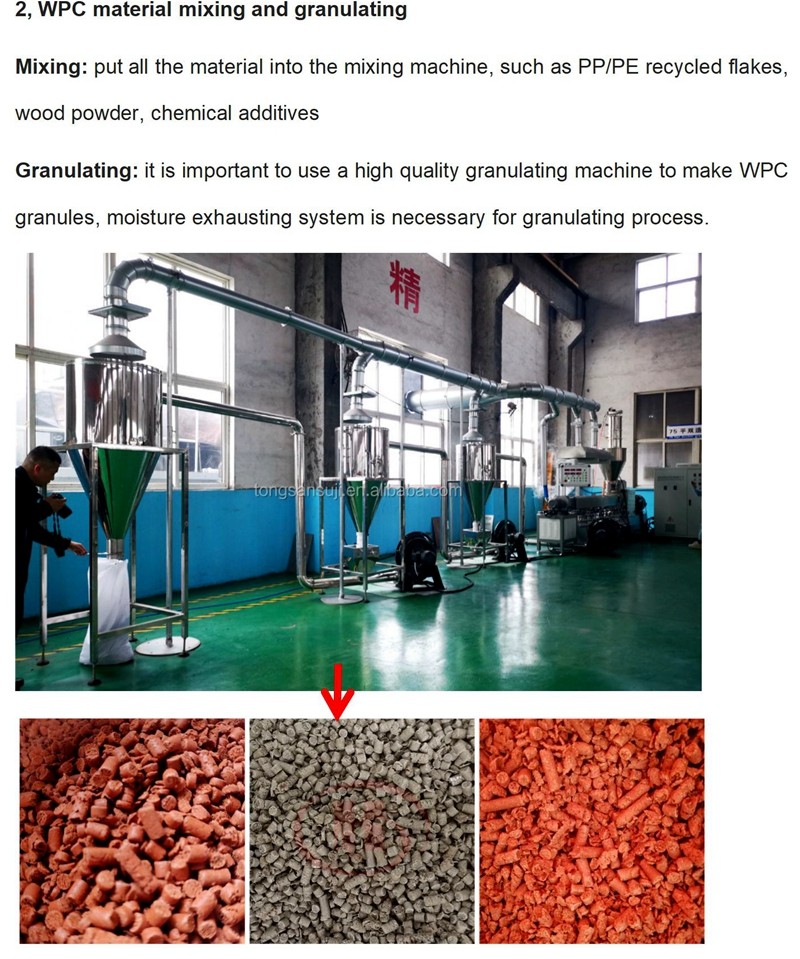

Tongsan Wood Plastic WPC machine is developed for using recycled PP/PE plastic mixing with agriculture wastage(such as wood sawdust, rice husk, rice straw, wheat straw) to make eco-friendly construction products, the max. wood percentage can be 70%.

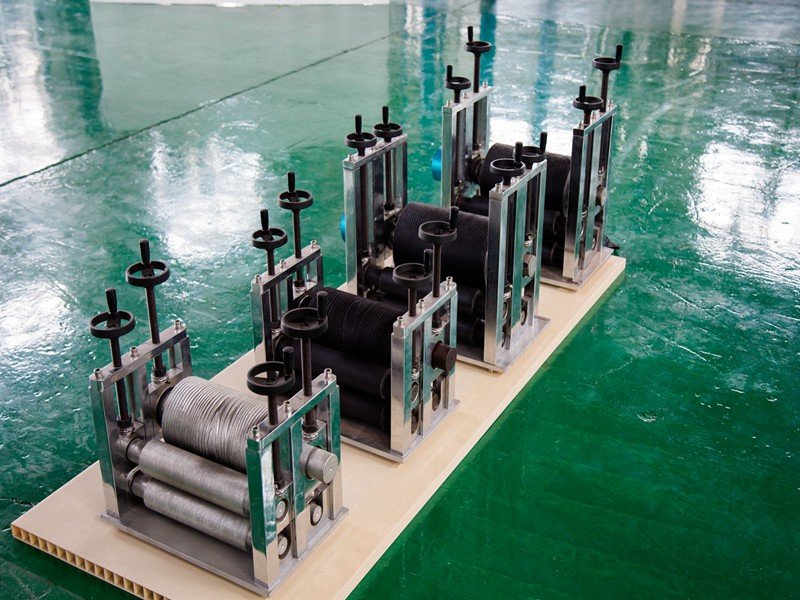

The Wood Plastic WPC machine is used for making WPC profiles by Wood and Plastic composition, such as WPC decking, WPC wall cladding, WPC fencing, WPC pergola, WPC post, etc...

PP PE Wood Plastic Composite WPC decking production machine turnkey plant