16-32mm Four Cavity PVC UPVC Electric conduit Pipe Making Machine

4 cavity output PVC pipe extrusion machine can produce 16-32mm PVC Pipe for electric conduit, water supply and drainage PVC UPVC pipe.

The advantage is it can provide 4 piece PVC pipes at the same time, improved prodcution efficiency.

4 cavity PVC Pipe Extrusion Machine Production Process:

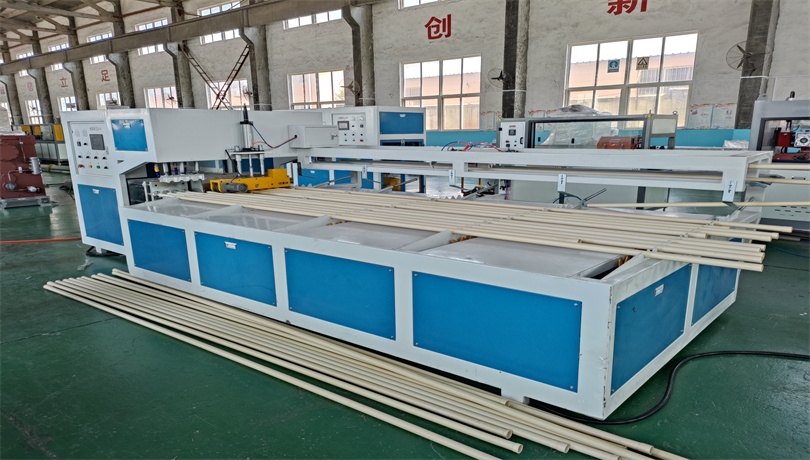

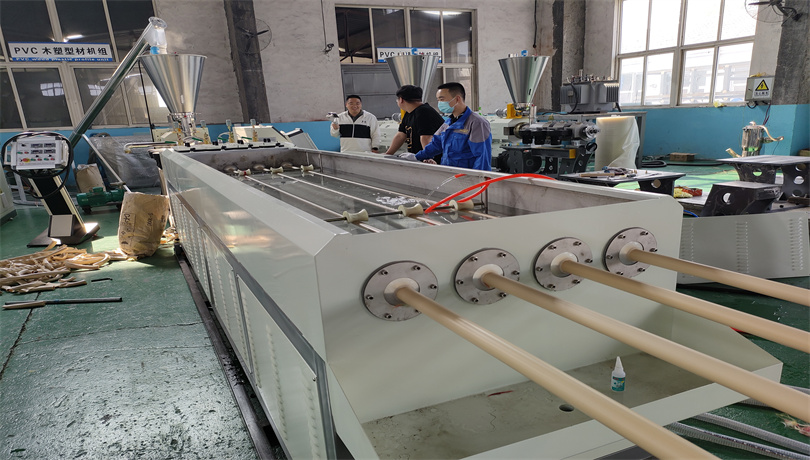

Raw Material Mixing-Feeder-Extruder- Die Head and Mould- Vacuum Calibration & Water Cooling Tank-Double Haul Off and Cutting Machine- Stacker

4 Cavity PVC Electric Pipe Production Line Model:

Model | Pipe diameter (mm) | Extruder type | Production speed(m/min) | Capacity (kg/h) | Installed power (kw) |

TS-40 | 16-40 | SJSZ-65/132 | 1-10 | 150-200 | 60 |

PVC Pipe Extrusion Line Equipment list and pictures:

1. Conical twin screw extruder:

3. PVC pipe mold: Mold material is 45 # quenched and tempered steel

4. Vacuum calibration tank: resistant to high pressure and corrosion resistance.

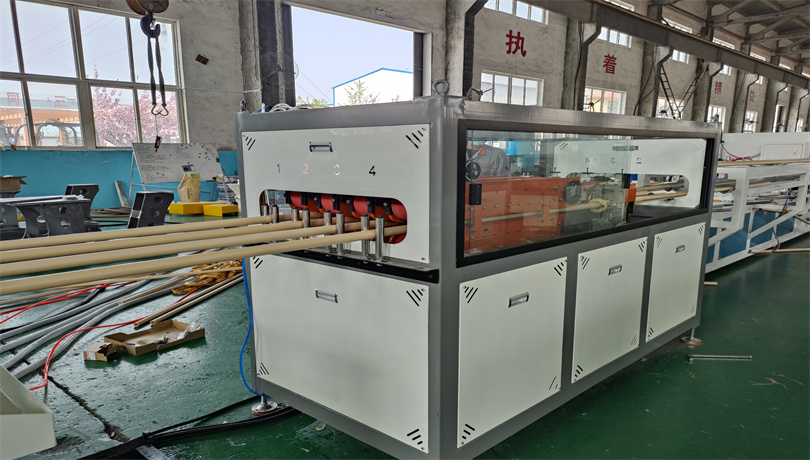

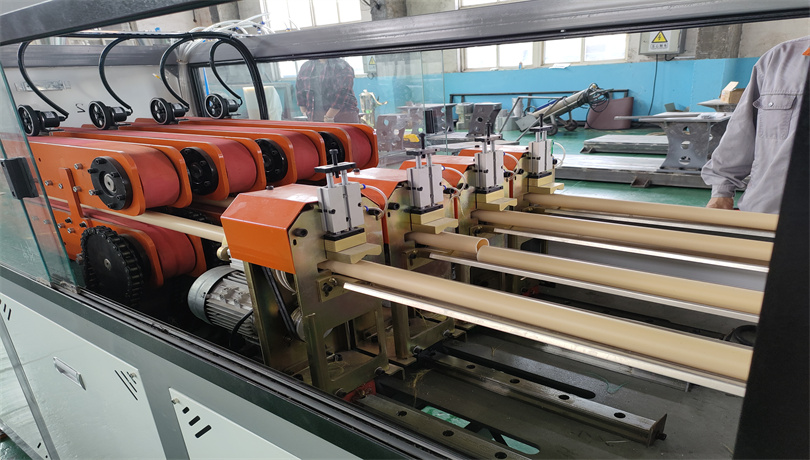

5. Hauling machine: It adopts frequency control mode.

6. Cutting machine: automatic cutting

7. Stacker: The pipe can be placed on the top of its.

8,Online four cavity PVC pipe belling machine