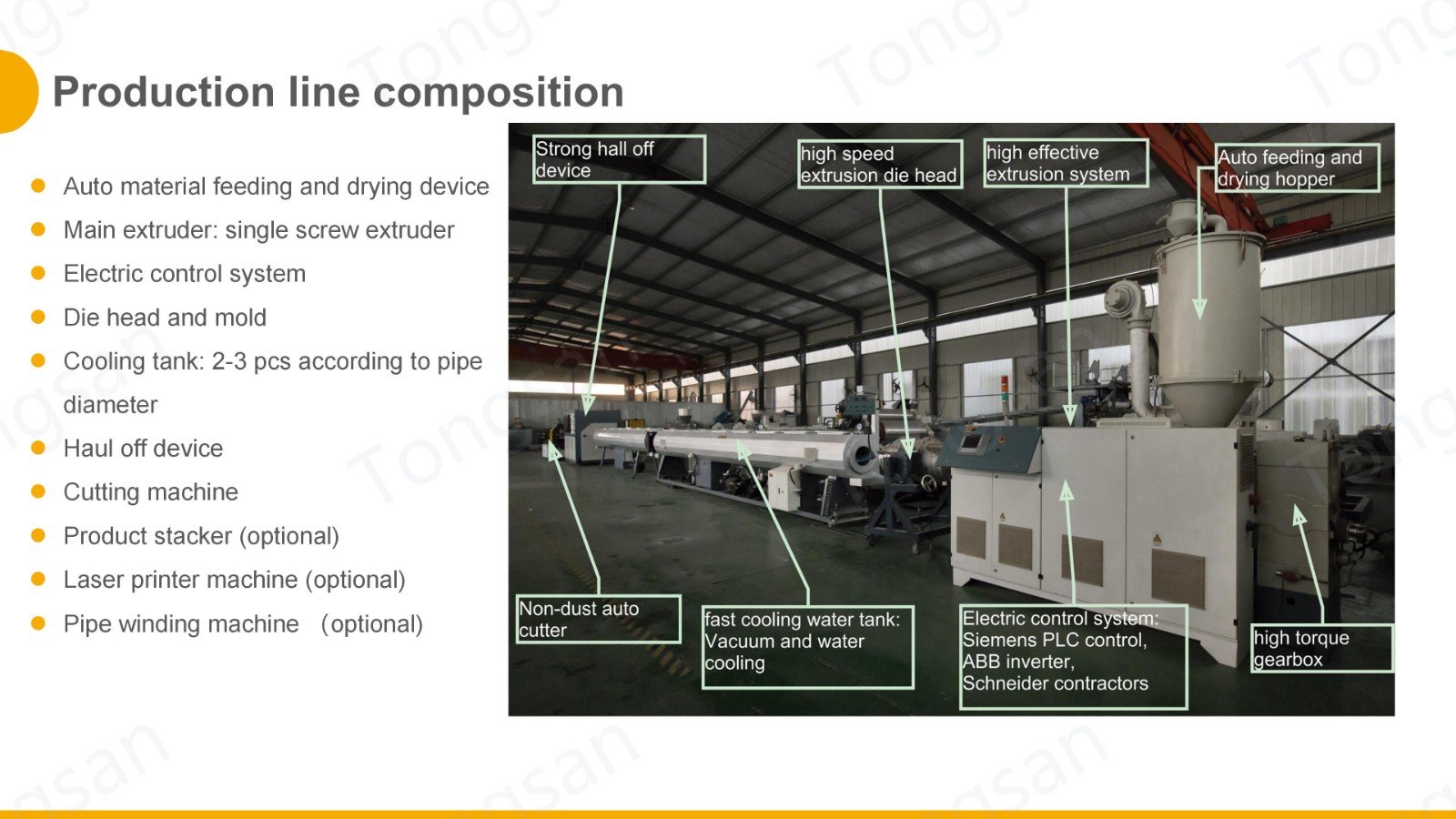

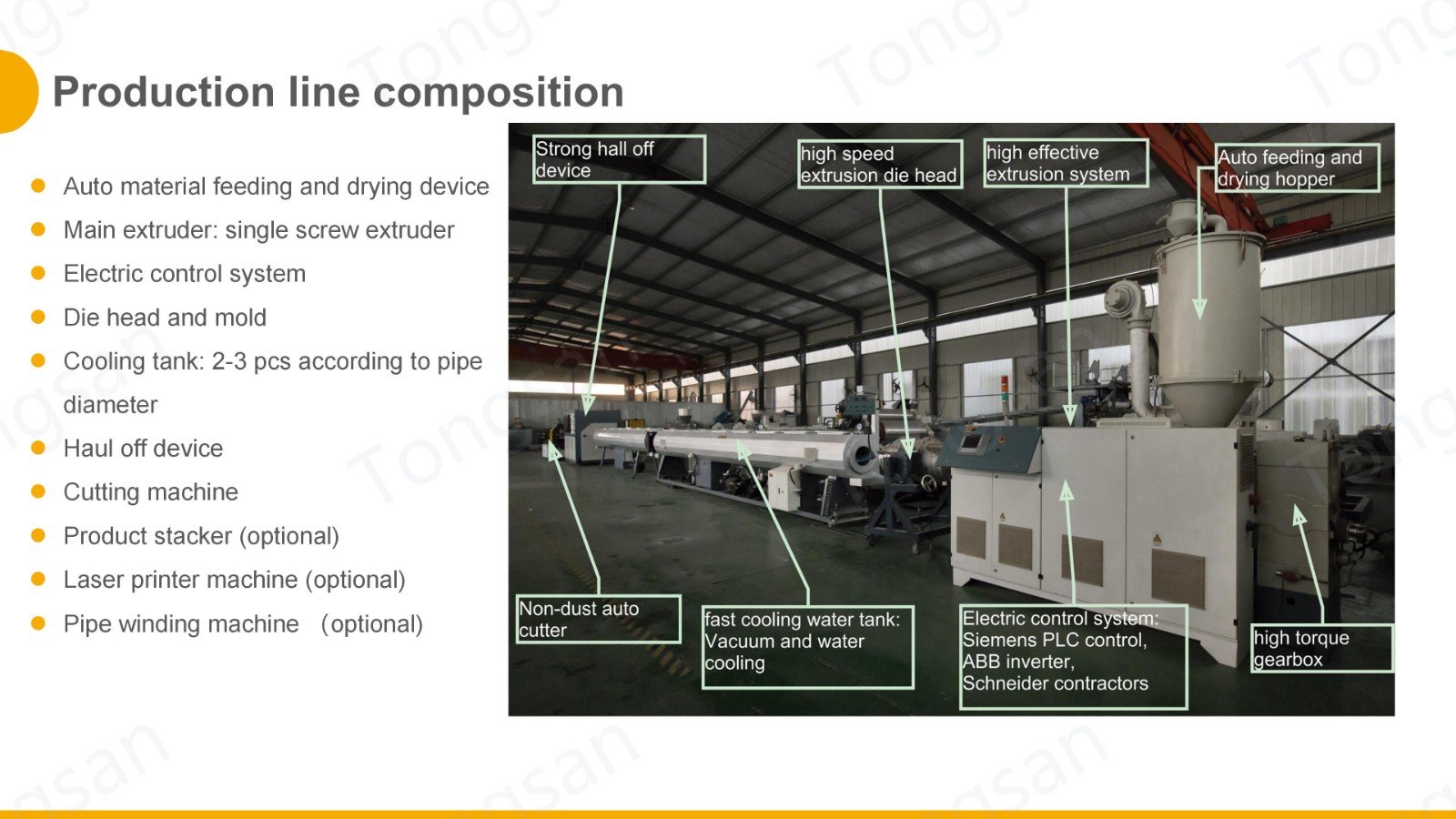

PPR HDPE PP Plastic pipe extrusion machine,

large diameter water and gas pipe production line

9-21mm PE pipe extrusion line for electric cable conduit

16-63mm PE pipe extrusion line for water supplying

16-63mm PPR pipe extrusion line for hot water supplying

75-250mm PE pipe extrusion line for gas and water supplying

110-315mm PE pipe extrusion line for gas and water supplying

315-630mm PE pipe extrusion line

PPR HDPE PP Plastic pipe extrusion machine,

large diameter water and gas pipe production line